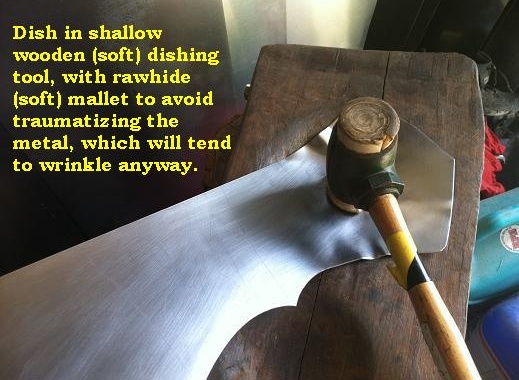

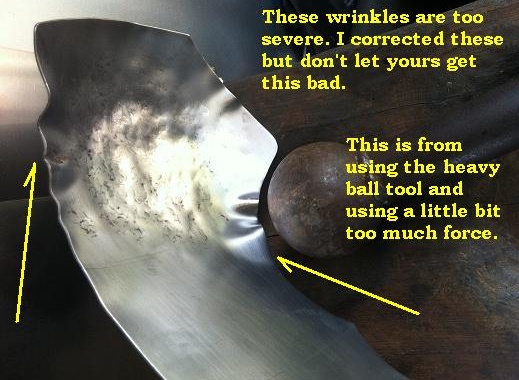

Think of mild steel as an agreeable surfer dude who is willing to try new crazy things. You negotiate and he’s okay with it. But don’t try to bully him – he gets upset. So we form the metal with some gradual progress and many patient hammer strokes, rather than expect the shape to form itself with only a few of your awesome hammer strokes.

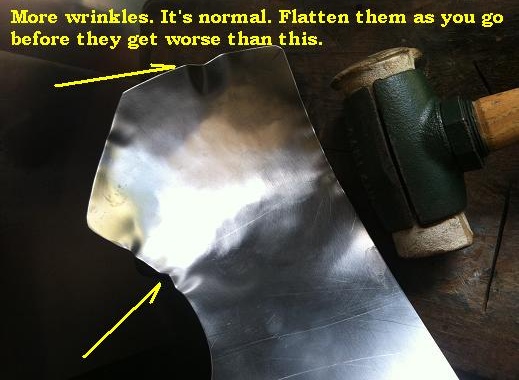

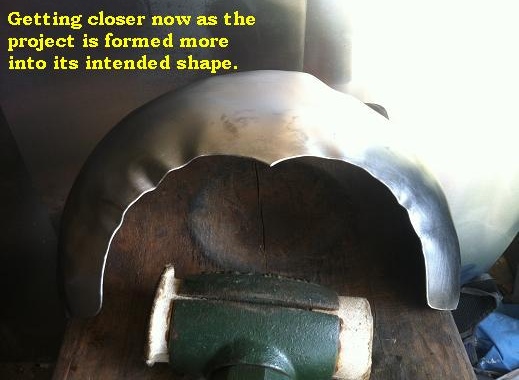

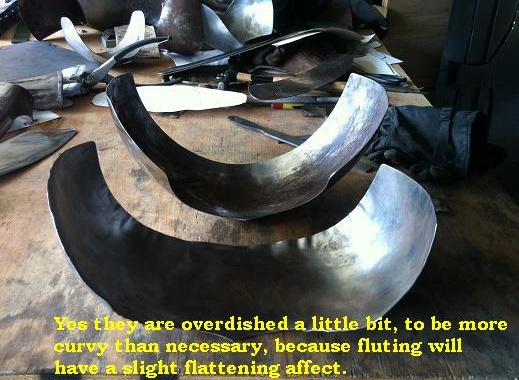

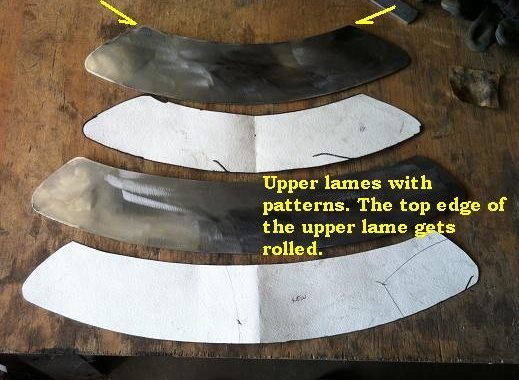

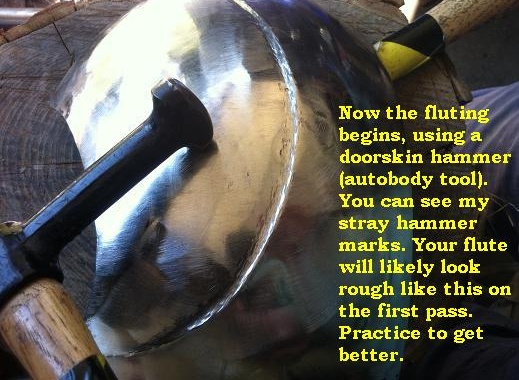

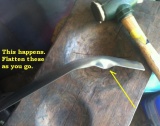

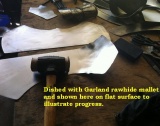

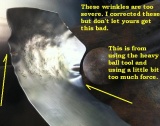

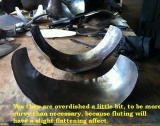

The metal is being shifted by your work, so wrinkles will happen. It’s normal. Flatten them out (on a mushroom stake) as you go, to prevent them from becoming too severe. Dish some more, flatten wrinkles. Repeat. The wider areas, both in front and behind the shoulder, should be dished first. The narrower area, directly over the shoulder, should be dished after them.

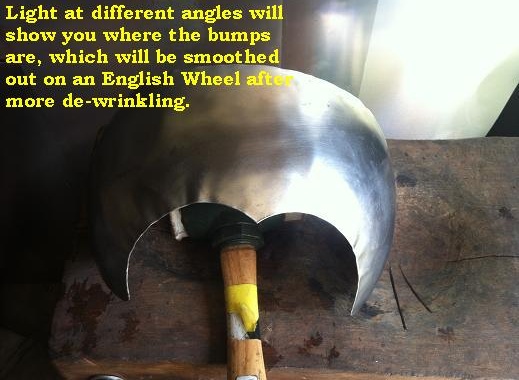

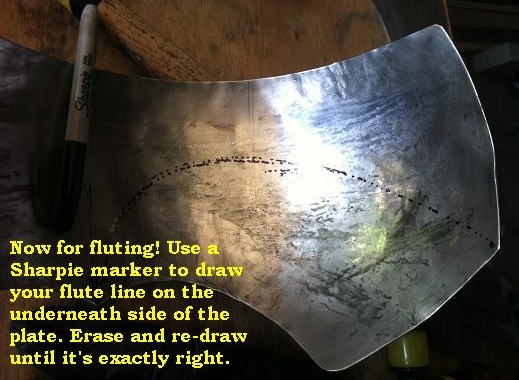

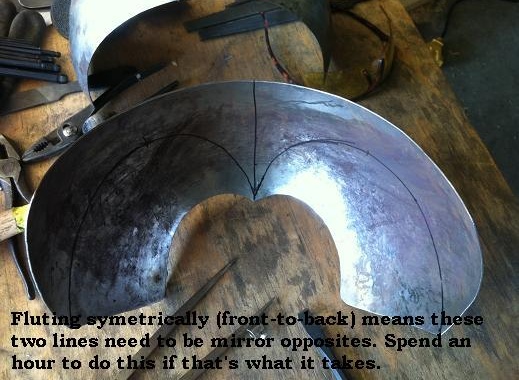

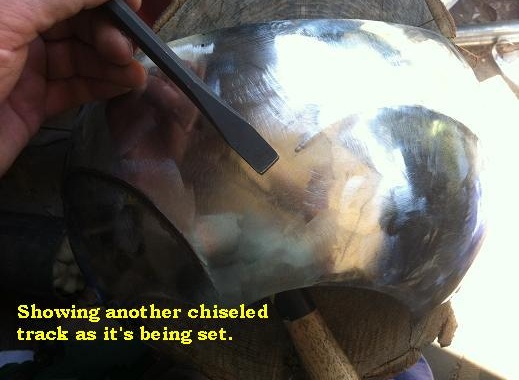

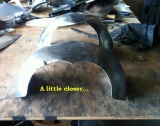

Often hold your work up to the light (sunlight works best) and identify unwanted variations in the surface shape. Before you install the fluting, take the time to get a uniformly semi-smooth surface. Then take it to the English Wheel for getting the surface ultra-smooth.

Be very careful using an English Wheel! Always use padded leather gloves, and always keep both hands on the outside of the piece – never push the piece from in front or pull it from behind. Instead, hold it firmly on left and right and glide the metal between the wheels. If you’re doing it right, you won’t shove your fingers toward the wheels from the front, or pull them into the wheels from behind. It is very easy to relax your “hand posture” and injure yourself with this tool, especially since you change the metal’s direction through the wheels so much.